CONCRETE OVERLAYS IN AUSTIN, TX

oncrete overlays are an alternative for both ornamental and restorative purposes. This method includes putting an even layer of concrete on an existing surface, resulting in a fresh and modern appearance without the need for costly renovation.

ATX Stained Concrete provides an array of concrete overlay services to help you in transforming your concrete surfaces into useful and aesthetically beautiful flooring. Our professionals will work with you to get the final result you desire, ranging from textured finishes like wood, tile, or stone to seamless concrete.

Whether you want to improve the aesthetic of your interior or exterior surfaces, a concrete overlay may offer a great option that fits your specific style and needs. Contact us today to learn more about our services and how we can ass

WHEN DO YOU NEED A CONCRETE OVERLAY?

SURFACE DAMAGE

If your concrete has cracks, chips, or other flaws, a concrete overlay can be applied to fix and hide this damage.

OUTDATED APPEARANCE

A concrete overlay can be used to give an aging concrete surface a new and stylish appearance.

CUSTOMIZATION

IA concrete overlay offers a variety of colors, textures, and patterns to your taste and allows you to create a unique and personalized look for your concrete surface.

CONCRETE OVERLAY PROCESS: WHAT TO EXPECT

With the right skills and tools, our team can complete concrete overlay work in a day or two. However, having a clear image of the procedure will help you know what to expect.

-

1. PREPARATION

The first stage in putting a concrete overlay is to thoroughly prepare the existing surface, removing any debris and repairing any cracks or chips.

-

2. PRIMING

After cleaning and drying the surface, a bonding agent or primer is put on to ensure excellent overlay adhesion.

-

3. APPLICATION

After that, the concrete overlay is applied to the surface with a trowel, squeegee, or spray. To achieve the desired effect, the overlay can be textured, colored, or patterned.

-

4: CURING

The concrete overlay must cure and set properly, which normally takes less than 48 hours depending on the type of overlay material and the weather conditions.

-

5. FINISHING

After the overlay has set, any rough edges are smoothed and the surface is cleaned in preparation for any additional treatments, such as staining or sealing.

Types of Stained Floors

A concrete overlay technique allows us to create an innovative style! Don’t limit your imagination to a basic grey look because we have limitless options with decorative concrete.

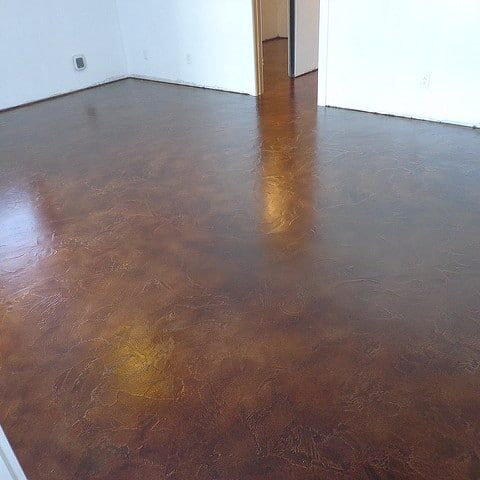

- CONCRETE STAINING: We offer acid stains and dyes that can create a variety of colors and finishes, giving you virtually limitless options for improving the aesthetic of your concrete surface.

- TEXTURING AND ENGRAVING: We may also add texture to your concrete overlay to give it a one-of-a-kind and personalized look. This can include natural patterns, graphics, and even logos.

- SEALING: Sealing is a critical process for protecting your concrete overlay from wear and tear. We provide a variety of sealing solutions that can create a number of finishes based on your preferences.

Gallery

Stained concrete floors add a touch of elegance and uniqueness to any space. The process involves applying a chemical stain to the concrete, which reacts with the minerals in the concrete to create a permanent color change. They are highly durable, low-maintenance, and resistant to moisture and wear, making them suitable for both residential and commercial spaces. Stained concrete floors are a cost-effective alternative to traditional flooring options and can significantly enhance the aesthetic appeal of any property.